YGD Series

The company is committed to do fine series of products, to provide quality services for the military industry; strong research and development technology, speed up the development of new products. We focus on the military market, is the electrical connector research, production base, and strive to contribute to the development of China's national defense industry!

Key words:

Electrical connector

Classification:

Hotline:

- Product Description

-

- Commodity name: YGD Series

- Commodity ID: 1139600761646895104

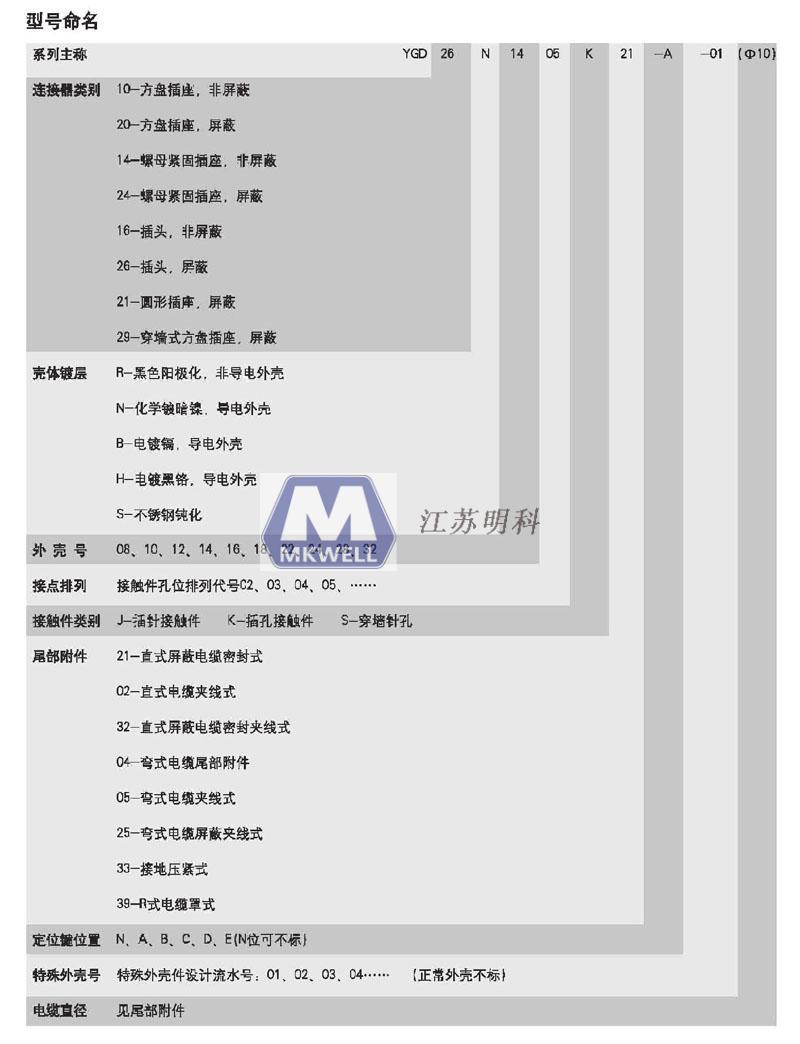

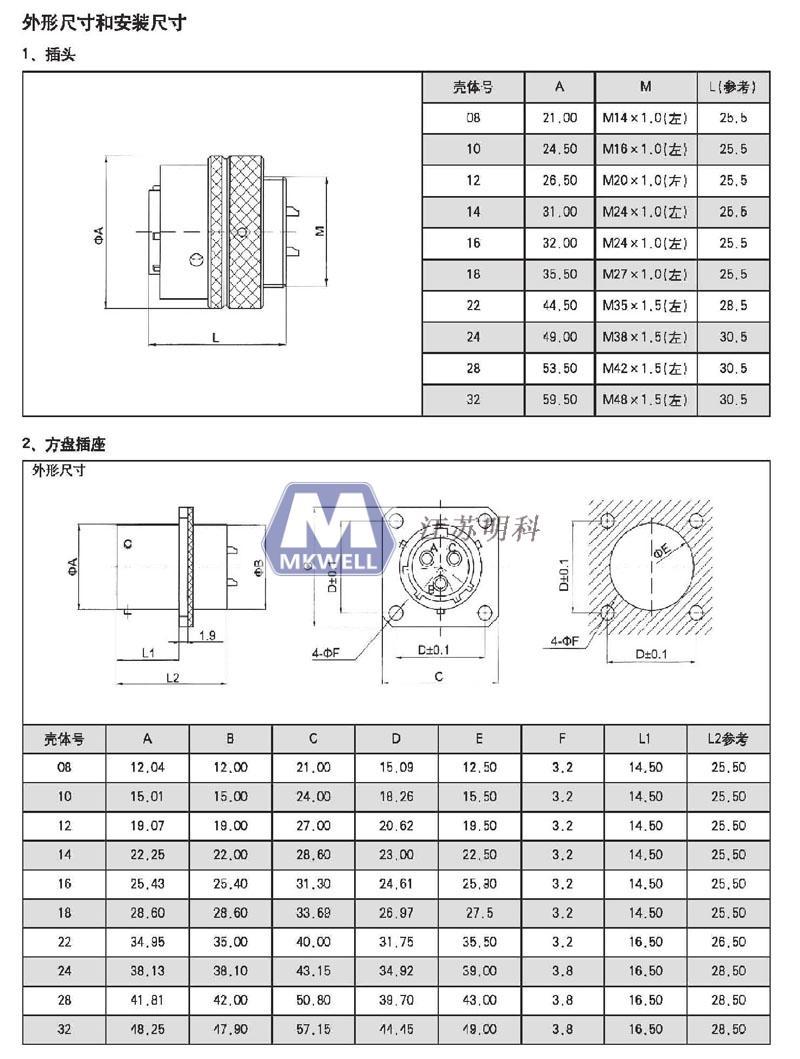

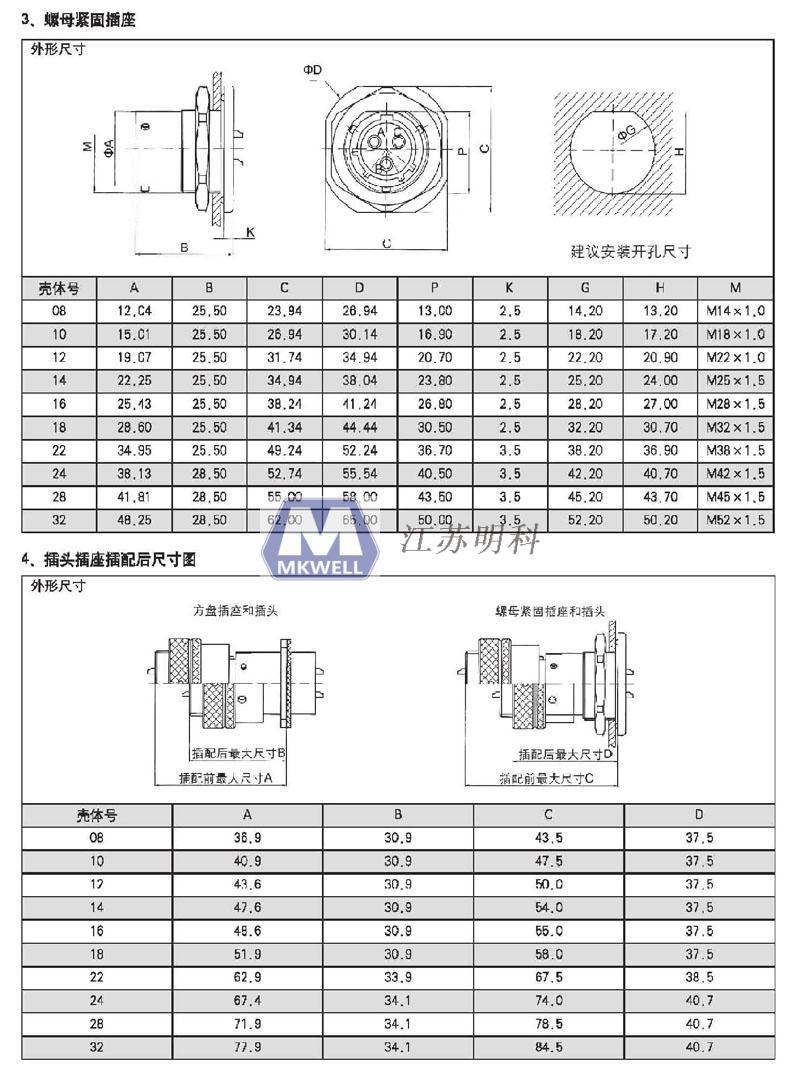

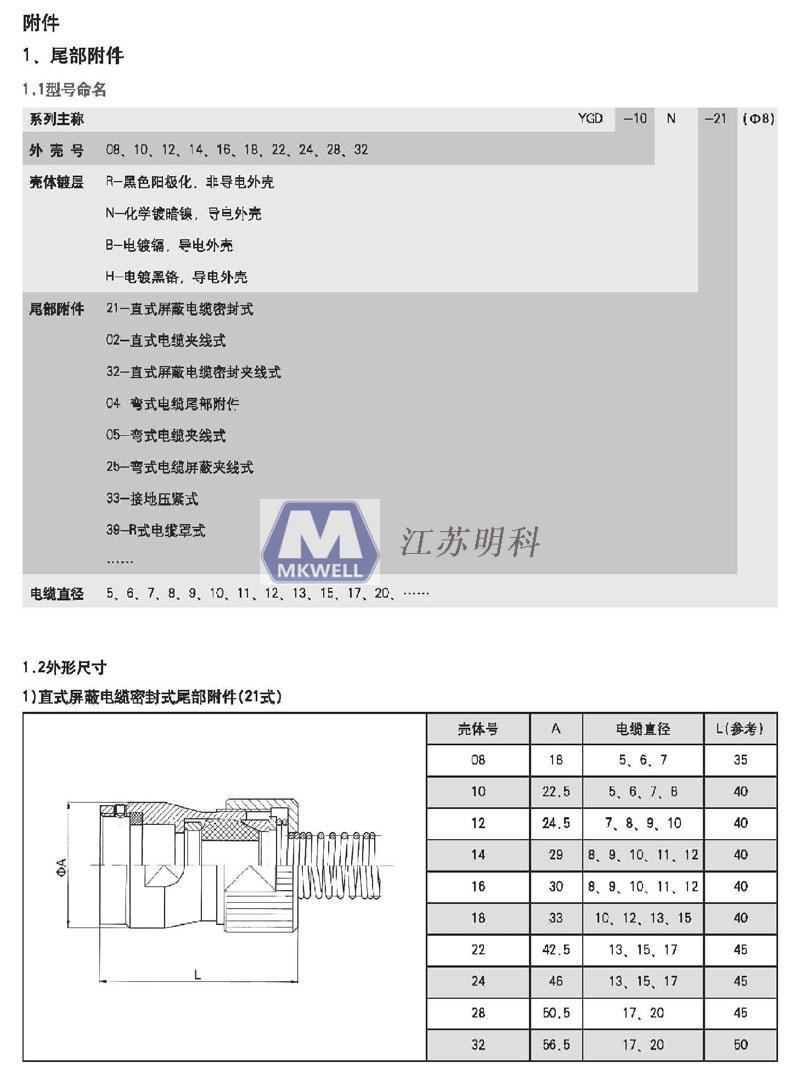

Selection of Electrical Connectors

It is not an easy task for users to select connectors that meet a series of requirements from a large variety of connectors. For example, the size and shape of the connector, the type of insulating material, the metal material and coating type of the contacts, as well as the termination technology, are all directly related to the space available in the system, performance requirements, and interconnection requirements. Users can select satisfactory connectors based on their basic understanding of connectors and starting from performance requirements (such as electrical performance, mechanical performance, environmental performance, and termination technology).

Electrical Parameter Requirements

When selecting electrical connectors, the first consideration should be the voltage and current requirements, followed by the following electrical parameters:

Contact resistance - For low-impedance circuits, when the connector is in series in the circuit, contact resistance is a key parameter.

Maximum current - Limited by the electrical connector and the gauge of the wire used.

Maximum voltage - Depends on the gap between circuits (i.e., contact spacing and creepage distance) and the insulating materials used in the connector.

Mechanical Parameter Requirements

In addition to considering the space and size limitations occupied by the connector, the following mechanical parameters must also be considered: vibration and shock - select the appropriate connector based on the expected vibration and shock requirements. As the flight speed of an aircraft or missile increases, vibration and shock intensify, leading to cracks in the insulating mounting plate, breakage at the connection point between the wire and the contact (soldering or crimping), and even separation of the mating components, especially during resonance. The rubber ring between the insulating mounting plate and the shell, as well as the elastic insulating mounting plate, have damping or cushioning effects.

Locking method - To prevent separation of the connector due to vibration, a safe and reliable locking method must be selected. The general locking method is a threaded connection with a safety wire, while the bayonet locking method not only has good vibration resistance but also allows for quick connection.

Positioning key - To prevent misalignment of similar connectors, several types of positioning key structures can be selected.

Installation method - Indicates whether it is front-mounted or rear-mounted.

Maintenance requirements - Since the actual maintenance situation may not be consistent with the expected connection and disconnection, possible maintenance conditions should be considered to select appropriate termination methods, installation methods, allowable mating forces, etc.

The environment in which the connector is used and transported has a significant impact on its performance, so the appropriate connector should be selected based on the expected environmental conditions.

Operation and Use of Electrical Connectors

Connection and Disconnection

When connecting the plug and socket of the connector, due to the blind mating function of the plug and socket, first insert the guiding section on the head into the socket, then rotate the plug. Once the five keys are correctly positioned, rotate the connecting nut clockwise, and the three locking pins will quickly enter the three curved grooves. After rotating about 120 degrees, a "click" sound will be heard, indicating that the plug and socket are correctly positioned and locked. For disconnection, gently push the connecting nut forward and rotate it counterclockwise, and the plug and socket will separate smoothly.

When wiring the connector, it must be terminated according to the corresponding contact number.

Power must not be applied before the connector is locked.

Ordering Instructions

After users have selected the connector, they should specify the following content in the contract or order.

* Product name and model

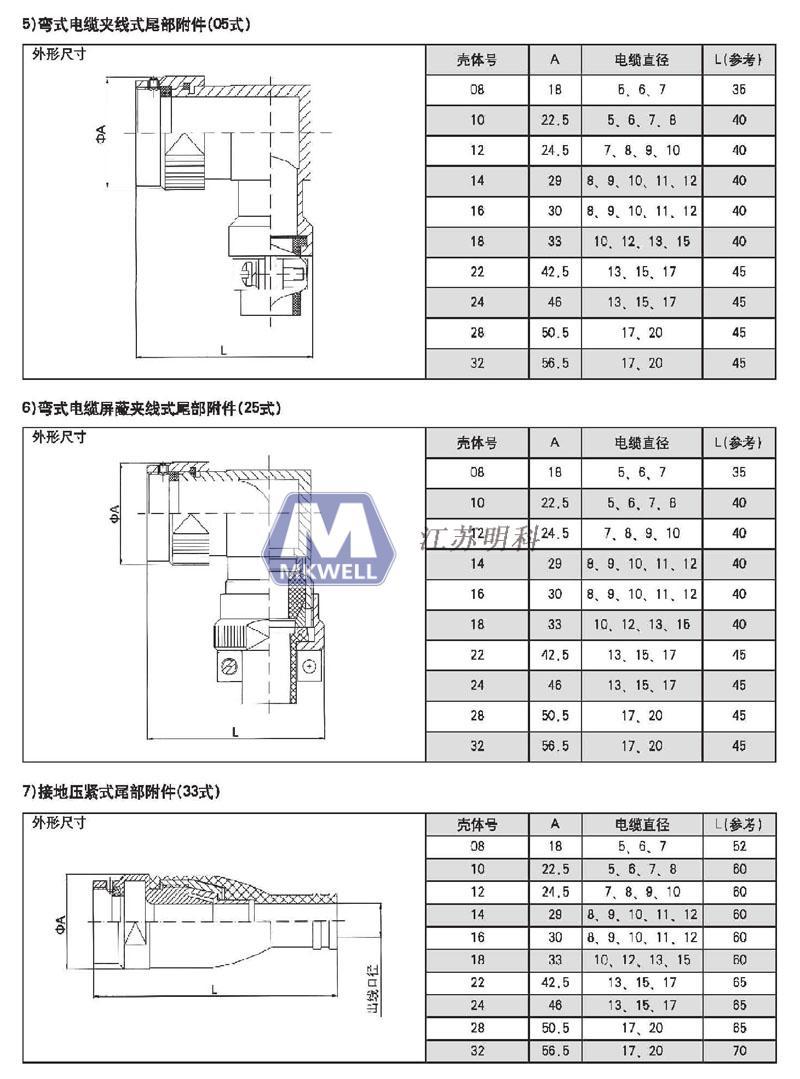

* Optional accessory model (as needed)

* Quantity

Optional cable accessories, crimping and uncrimping tools must be ordered separately. The model of the selected cable accessories can be written after the corresponding product model with a '+' in between.

If users have special requirements for electrical connectors, we will sincerely meet their needs to improve or develop new electrical connectors.

Recommend Products

Message

We will contact you within one working day. Please pay attention to your email.

Jiangsu Mingke Photoelectric Technology Co.,Ltd.

Address: Da Sheng Industrial Park, Zhenxing North Road, Urban Area, Taixing City, Jiangsu Province

Phone:0523-87591866、0523-87591266

Mobile:18796784030

Fax: 0523-87591288

Website:www.mkwell.com.cn

Email:jiangsumk@163.com

Copyright:Jiangsu Mingke Photoelectric Technology Co.,Ltd.